What are the requirements for the formulation and process of wood grain heat transfer powder coating?

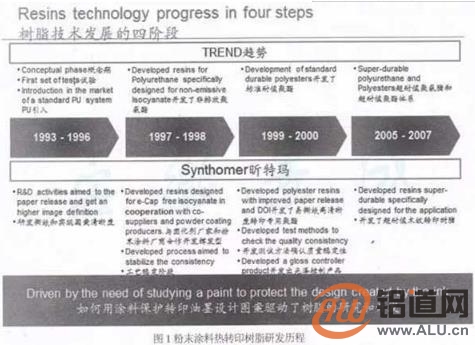

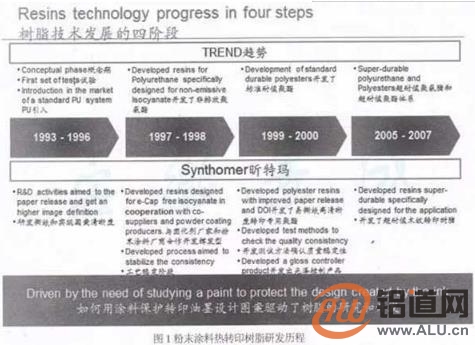

Heat transfer printing technology has been applied to the production of fabric transfer printing for a long time. With the rapid development of science and technology, heat transfer printing technology has been applied more and more widely. Thermal transfer can be divided into hot press transfer type and thermal sublimation transfer type. This paper discusses the thermal sublimation transfer which is popular in the powder industry. It has become a popular trend to transfer exquisite patterns onto the powder coating to change the metal surface to form wood grain effect or other patterns. The application of this green environmental protection technology has changed people's dependence on solid wood and reduced excessive deforestation. The technology was jointly developed by Italian powder polyester resin manufacturers, powder coating manufacturers, spraying plants and users, including Tingtema, in the 1990s according to the market's pursuit of popular trends, and was successfully applied to profiles and various substrates. Figure 1 shows the R&D and development history of heat transfer resin.

1 Basis of Heat Transfer Printing Technology

1.1 Wood grain heat transfer printing process

The thermal sublimation dye ink is printed on the transfer paper or transfer film, and then the transfer film/paper pattern is transferred to the powder coating through the combined action of vacuum, heat and pressure.

1.2 Sublimation/condensation

Sublimation is the change process of substances from the direct phase of solid to gas, and condensation is the change of substances from the direct phase of gas to solid. The high temperature sublimates the solid dye from the transfer paper or membrane and penetrates into the powder coating structure. After sublimation, the dye is cooled and condensed into a solid state from the gas, thus becoming a part of the powder coating.

1.3 Dyes and inks

Solid ink sublimates into gas under heating conditions, and can be converted into solid again under cooling.

1.4 Transfer paper or film

The carrier of pattern design, printing and transfer reproduction.

1.5 Base material

Metal or other substrates that can resist 200 ℃, including ceramics, glass and high and low light powder spraying decorative substrates.

2 Application of heat transfer printing

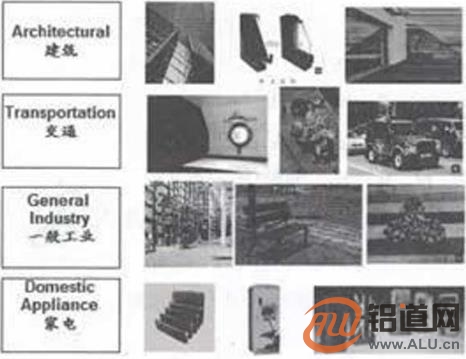

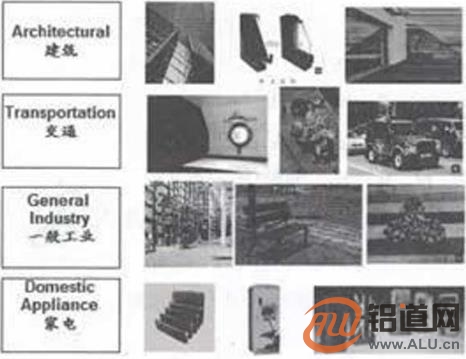

Where there is a need for appearance change, there is a transfer. According to market segmentation, powder heat transfer printing is widely used in the fields of construction, transportation, general industry and household appliances, such as doors and windows, garages, decorative ceilings, store fixtures, shelves, display cabinets, tables, awnings, benches, tables and chairs, decorative platforms, armrests, household appliances, kitchenware, refrigerators, barbecue equipment, clocks, sunshine rooms, luxury yacht interiors, etc. See Figure 2 for a detailed overview.

3. Mechanism of sublimation heat transfer printing of powder coatings and its influencing factors

3.1 Transfer mechanism and process flow

Generally, substances are divided into four states, namely, solid, liquid, gas and plasma states. Figure 3 describes the conversion between phase states. Sublimation thermal transfer printing is to realize the penetration and migration of dye molecules from transfer paper or transfer film to the substrate powder coating by using the sublimation and condensation of dye ink, so as to realize the transfer of patterns, forming wood grain or other desired effects. Figure 4 shows the process of transfer printing.

3.1 Basis of Heat Transfer Printing Technology

1.1 Wood grain heat transfer printing process

The thermal sublimation dye ink is printed on the transfer paper or transfer film, and then the transfer film/paper pattern is transferred to the powder coating through the combined action of vacuum, heat and pressure.

1.2 Sublimation/condensation

Sublimation is the change process of substances from the direct phase of solid to gas, and condensation is the change of substances from the direct phase of gas to solid. The high temperature sublimates the solid dye from the transfer paper or membrane and penetrates into the powder coating structure. After sublimation, the dye is cooled and condensed into a solid state from the gas, thus becoming a part of the powder coating.

1.3 Dyes and inks

Solid ink sublimates into gas under heating conditions, and can be converted into solid again under cooling.

1.4 Transfer paper or film

The carrier of pattern design, printing and transfer reproduction.

1.5 Base material

Metal or other substrates that can resist 200 ℃, including ceramics, glass and high and low light powder spraying decorative substrates.

2 Application of heat transfer printing

Where there is a need for appearance change, there is a transfer. According to market segmentation, powder heat transfer printing is widely used in the fields of construction, transportation, general industry and household appliances, such as doors and windows, garages, decorative ceilings, store fixtures, shelves, display cabinets, tables, awnings, benches, tables and chairs, decorative platforms, armrests, household appliances, kitchenware, refrigerators, barbecue equipment, clocks, sunshine rooms, luxury yacht interiors, etc. See Figure 2 for a detailed overview.

3. Mechanism of sublimation heat transfer printing of powder coatings and its influencing factors

3.1 Transfer mechanism and process flow

Generally, substances are divided into four states, namely, solid, liquid, gas and plasma states. Figure 3 describes the conversion between phase states. Sublimation thermal transfer printing is to realize the penetration and migration of dye molecules from transfer paper or transfer film to the substrate powder coating by using the sublimation and condensation of dye ink, so as to realize the transfer of patterns, forming wood grain or other desired effects. Figure 4 shows the process of transfer printing.

1 Basis of Heat Transfer Printing Technology

1.1 Wood grain heat transfer printing process

The thermal sublimation dye ink is printed on the transfer paper or transfer film, and then the transfer film/paper pattern is transferred to the powder coating through the combined action of vacuum, heat and pressure.

1.2 Sublimation/condensation

Sublimation is the change process of substances from the direct phase of solid to gas, and condensation is the change of substances from the direct phase of gas to solid. The high temperature sublimates the solid dye from the transfer paper or membrane and penetrates into the powder coating structure. After sublimation, the dye is cooled and condensed into a solid state from the gas, thus becoming a part of the powder coating.

1.3 Dyes and inks

Solid ink sublimates into gas under heating conditions, and can be converted into solid again under cooling.

1.4 Transfer paper or film

The carrier of pattern design, printing and transfer reproduction.

1.5 Base material

Metal or other substrates that can resist 200 ℃, including ceramics, glass and high and low light powder spraying decorative substrates.

2 Application of heat transfer printing

Where there is a need for appearance change, there is a transfer. According to market segmentation, powder heat transfer printing is widely used in the fields of construction, transportation, general industry and household appliances, such as doors and windows, garages, decorative ceilings, store fixtures, shelves, display cabinets, tables, awnings, benches, tables and chairs, decorative platforms, armrests, household appliances, kitchenware, refrigerators, barbecue equipment, clocks, sunshine rooms, luxury yacht interiors, etc. See Figure 2 for a detailed overview.

3. Mechanism of sublimation heat transfer printing of powder coatings and its influencing factors

3.1 Transfer mechanism and process flow

Generally, substances are divided into four states, namely, solid, liquid, gas and plasma states. Figure 3 describes the conversion between phase states. Sublimation thermal transfer printing is to realize the penetration and migration of dye molecules from transfer paper or transfer film to the substrate powder coating by using the sublimation and condensation of dye ink, so as to realize the transfer of patterns, forming wood grain or other desired effects. Figure 4 shows the process of transfer printing.

AboutRelying on high-end green environmental protection technology, taking creation as the soul, adhering to the advanced concept o...

AboutRelying on high-end green environmental protection technology, taking creation as the soul, adhering to the advanced concept o... Product and solutionProvide high-end powder. The overall solution of raw and auxiliary materials, supporting equipment, process and painting will make your life more colorful and green.

Product and solutionProvide high-end powder. The overall solution of raw and auxiliary materials, supporting equipment, process and painting will make your life more colorful and green. ContactBased in Linqu, we have made a single breakthrough, established multiple R&D centers, and covered the whole country in a network way.

ContactBased in Linqu, we have made a single breakthrough, established multiple R&D centers, and covered the whole country in a network way.