Product profile

Organic powder with metal pigment using bonding technology to bond has reached the electroplating, metal luster,crystal Satin pearl bright luxury decoration effect. The application of the colorful gorgeous metallic powder coatings is more widely. It is the mainstream art type powder coating at present, and this kind of powder coating does not contain Pb, Cd, Hg, Six valence chromium and any other toxic substances.

Bonding process

Bonding process: Bottom powder with metallic pigment→melt→dispersed→mixed→bond→agglutination→adjustment→bonding powder products.

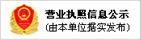

Product effect

MEIAO has developed a variety of new products, such as replacing the paint metal effect series products and the chameleon series products. According to the customer needs to prepare all kinds of effect of metal powder coatings successfully, such as effect of chromium alloy, hammer effect, all kinds of antique, flash, rainbow effect, etc.

Features

It has excellent corrosion resistance, mechanical properties, storability, salt fog resistance, moisture resistance and excellent chemical resistance and edge coverage resistance and color retention.

Density: (ASTM D792)1.2—1.8[g/cm³] depending on the color

Particle size: general average particle size30—35um,according to different applications.

Storage: under the environment of lower than 30 DEG C,dry indoor storage for 12 months.

The theory of spraying area: 9.0—13.8m² ( 100% utilization rate,with the film thickness of 60 mu m calculation,and the proportion of related. )

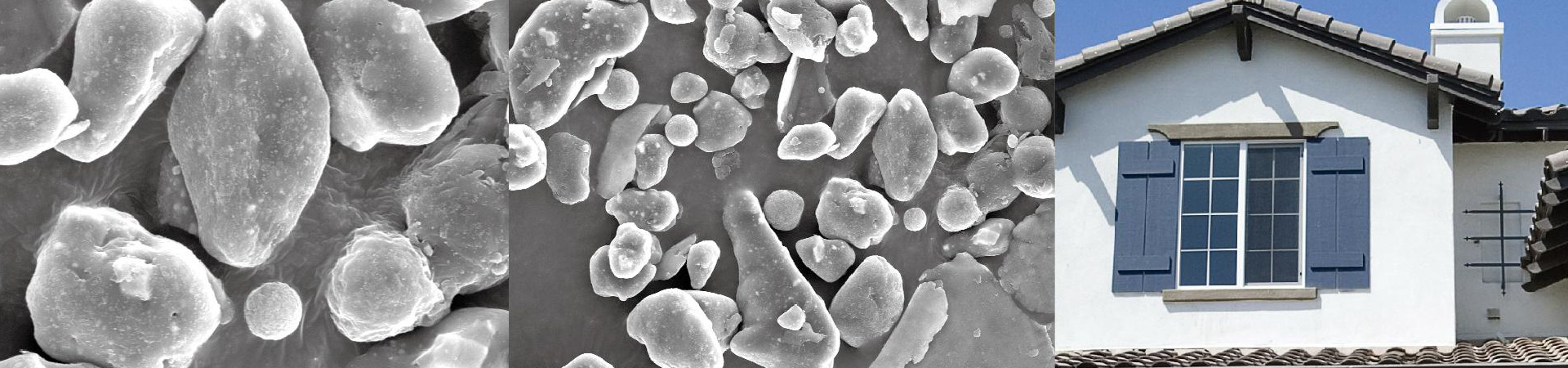

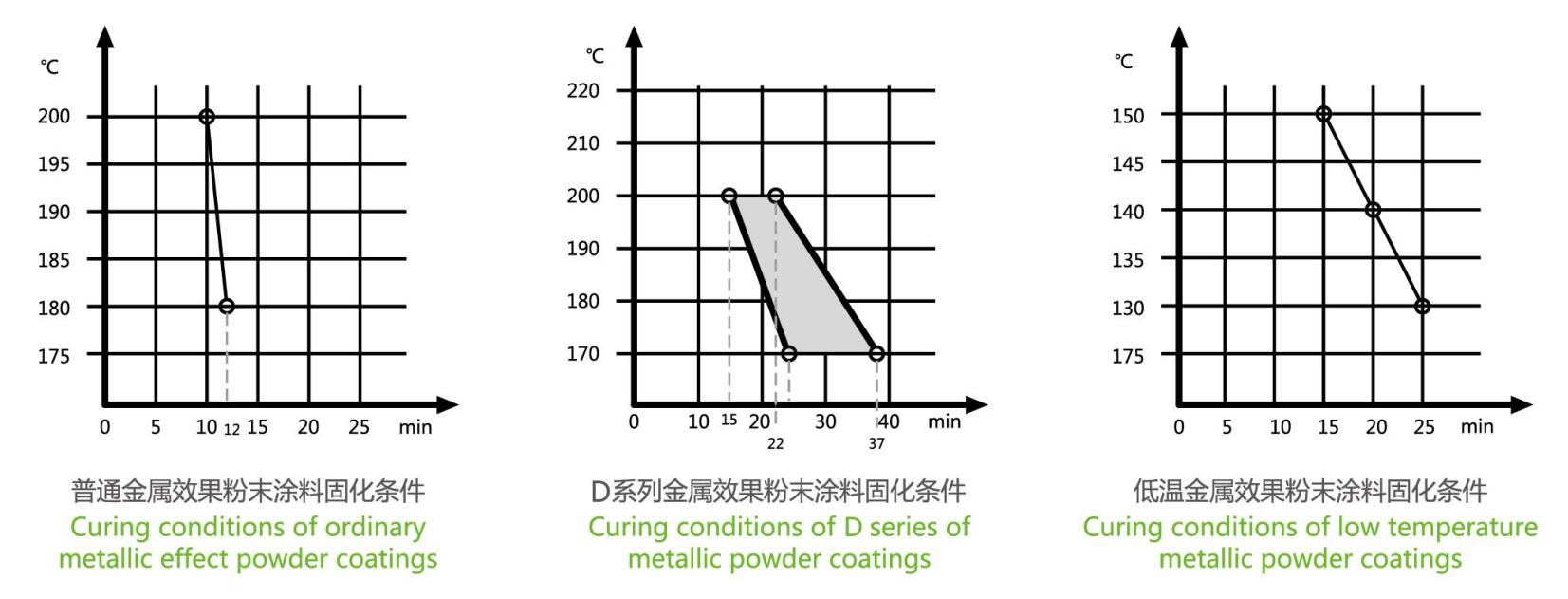

The curing parameter(Substrate temperature)

According to the different varieties and system, the curing conditions of existing metallic effect powder coatings is divided into the following three, the temperature referred to in the figure is the temperature of surface of substrate.

Because the formation of coating mechanical properties and weathering performance are before the full curing, and please read the curing parameter description carefully when you use of the product specificly.

AboutRelying on high-end green environmental protection technology, taking creation as the soul, adhering to the advanced concept o...

AboutRelying on high-end green environmental protection technology, taking creation as the soul, adhering to the advanced concept o... Product and solutionProvide high-end powder. The overall solution of raw and auxiliary materials, supporting equipment, process and painting will make your life more colorful and green.

Product and solutionProvide high-end powder. The overall solution of raw and auxiliary materials, supporting equipment, process and painting will make your life more colorful and green. ContactBased in Linqu, we have made a single breakthrough, established multiple R&D centers, and covered the whole country in a network way.

ContactBased in Linqu, we have made a single breakthrough, established multiple R&D centers, and covered the whole country in a network way.